Manufacturer

Rockwell Automation Allen-Bradley

Allen-Bradley

Allen-Bradley is a division of Rockwell Automation electrical products and solutions for industrial applications.

Allen-Bradley Video

(Video created in 2015 by the Treasures of the Electrical Industry team. Permission given to publish these history images.)

Phone Interview: Click Here

Mary Burgoon, Rockwell Automation

Paul Gieschen, Rockwell Automation

Richard Watson, Treasures of the Electrical Industry

THE ALLEN-BRADLEY COMPANY STORY

by Lynde Bradley, Allen-Bradley Founder

When recording the history of the Allen-Bradley Company, it seems appropriate that I introduce a character who played a short, but important role, and then passed from notice. This was Ralph Skidmore, a schoolmate at the 18th district school of Milwaukee, in 1893. He was just a typical, freckled, irresponsible healthy kid, like thousands of other American school kids.

He was known to some of his intimates as Banyan, due to some interest he had inadvertently and carelessly shown in the course of his school work in connection with the tree bearing name. Banyan, knowing that I was endowed with a boyish penchant for playing with electricity, decided it would be to my benefit to read a book from his older brother’s library, which he made it a point to bring to school and loan me. This is where Banyan makes his exit from the story and does not appear again.

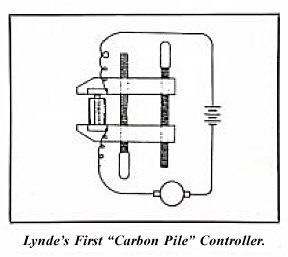

Carbon Pile

Lynde Bradley First Controller

All he did was to loan me the book, but that certainly was enough. This book was entitled “Electricity for Engineers” and was written by Charles Desmond. It contained a brief description of the electric lighting and distribution systems of about the year 1890 and before, and among the various devices described was what is known as the brush regulator. The function of this apparatus was to maintain a constant current in a series arc light circuit. It consisted, briefly, of a number of piles of rectangular carbon plates supported vertically in slate chutes of containers.

These carbon piles were subjected to pressure by means of solenoid operated lever. The carbon piles were connected in series with the line. It is not difficult for one skilled in the art to perceive that this contraption would tend to maintain the current more or less constant in the line as any increase in current would increase the pull on the solenoid, and thereby reduce the resistance of the carbon piles, which in turn would shunt more current from the generator field and reduce the impressed c.m.f. on the outside lines. The reverse would take place, if for some reason the current was weakened in the lighting circuit. The thing must have worked more or less badly, but that was considered good in the electrical art in those days, so it got by for a while.

…Reading about this regulator brought to my youthful mind for the first time that this variable contact resistance of carbon could be utilized for electrical control in other forms than the telephone transmitter. On the strength of this newly acquired knowledge, I built what might be called the first Allen-Bradley rheostat. As near as I can remember, I sawed eleven discs of carbon, 3/8 inch thick, from an old 5/8 inch diameter arc light electrode and placed these in the form of a column in a wooden tube, made from the hub of a magnet wire spool. The carbon column was a little longer than the tube, and the tube was fastened to one of the wooden jaws of a pattern marker’s clamp and so arranged that by screwing down the clamp, the column would be compressed. Pieces of tin plate had been fitted between the carbon column and the clamp jaws for terminals.

The work shop where this was made was in the cellar of my home and one of the proud possessions of this work shop was a toy wooden working lathe, known to the trade, I think, as the Goodell lathe. The lathe I had previously arranged to be driven by a small battery motor which operated on something like six volts, and the first step after completing the first carbon pile rheostat was to fasten it within easy reach, so that the column set vertically to one of the ceiling rafters over the lathe, and was connected in series with one of the motor lines, and to my great delight and surprise, it worked splendidly. It gave almost infinite control of the motor speed and even got hot. The latter fact, I think, impressed me even more than its resistance characteristics.

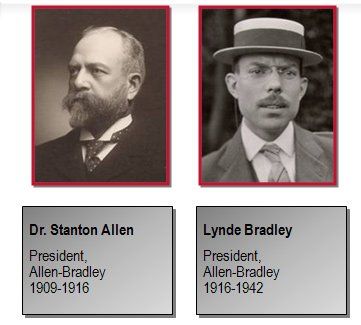

Allen-Bradley Founders

Dr. Allen and Lynde Bradley

From a boy’s viewpoint, it was a great success….As I have before mentioned, this was in 1893. Then in the year 1901: Dr. Allen would make this proposition; he would put up a thousand dollars; I was to build the model of the controller in my back yard where I had a small work shop in an old shed. He would help all he could and we would go halves on the results…

——————————-

Then in the year 1935, Mr. Lynde Bradley concluded: I can see nothing in the future but a greater Allen-Bradley Company.

Further reading on the Allen-Bradley history is on Rockwell Automation website.

MEMBERSHIP

Design by: PTI Solutions Group